Rapid Prototyping for SMEs: Why It Matters

- I-Solids

- Dec 23, 2025

- 5 min read

In today's fast-paced market, small and medium-sized enterprises (SMEs) face unique challenges that require innovative solutions. One such solution is rapid prototyping, a method that allows businesses to quickly create and test product ideas. This approach not only accelerates the development process but also enhances creativity and reduces costs. In this blog post, we will explore the significance of rapid prototyping for SMEs, its benefits, and practical examples of how it can be implemented effectively.

Understanding Rapid Prototyping

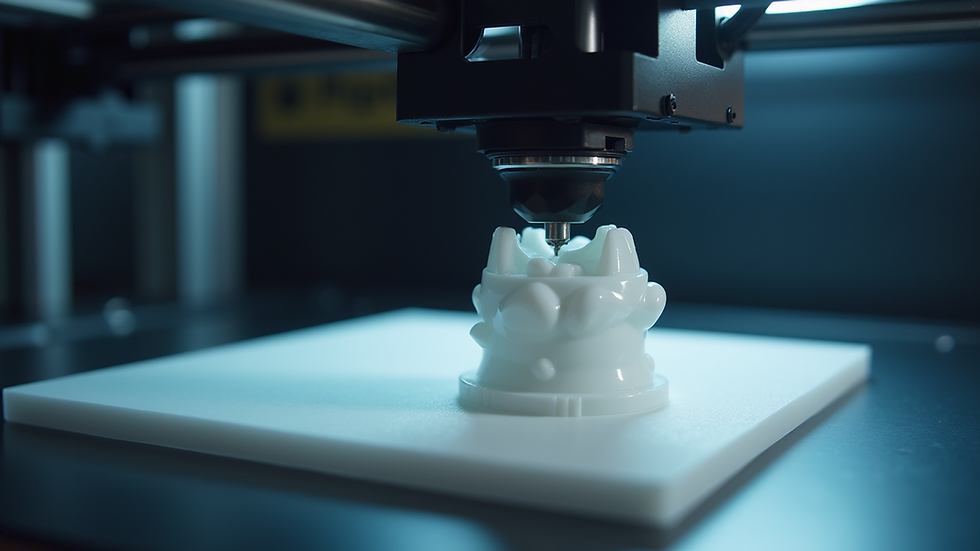

Rapid prototyping is a design process that emphasizes speed and efficiency. It involves creating a preliminary version of a product, often using 3D printing or other quick manufacturing techniques. The goal is to produce a tangible model that can be tested and refined based on user feedback.

Key Features of Rapid Prototyping

Speed: Prototypes can be developed in days rather than months.

Cost-Effectiveness: Reduces the financial risk associated with product development.

Flexibility: Allows for easy modifications based on testing and feedback.

User-Centric Design: Engages users early in the design process to ensure the final product meets their needs.

Why Rapid Prototyping Matters for SMEs

For SMEs, the ability to innovate quickly is crucial. Here are several reasons why rapid prototyping is particularly beneficial for smaller businesses:

Accelerated Time to Market

In a competitive landscape, being first can make a significant difference. Rapid prototyping enables SMEs to bring products to market faster. By quickly iterating on designs, businesses can respond to market demands and capitalize on emerging trends.

Enhanced Collaboration

Rapid prototyping fosters collaboration among teams. Designers, engineers, and stakeholders can work together more effectively when they have a physical model to discuss. This collaborative environment leads to better ideas and solutions.

Reduced Development Costs

Developing a product can be expensive, especially for SMEs with limited budgets. Rapid prototyping minimizes costs by allowing businesses to test concepts before committing to full-scale production. This approach reduces the likelihood of costly mistakes.

Improved Product Quality

By testing prototypes with real users, SMEs can gather valuable feedback early in the development process. This user input helps identify potential issues and areas for improvement, leading to a higher-quality final product.

Practical Examples of Rapid Prototyping in Action

To illustrate the effectiveness of rapid prototyping, let's look at a few real-world examples of SMEs that have successfully implemented this approach.

Case Study 1: A Local Furniture Maker

A small furniture company wanted to design a new line of chairs. Instead of investing heavily in traditional manufacturing methods, they opted for rapid prototyping. Using 3D printing, they created several chair prototypes in a matter of weeks. By testing these prototypes with potential customers, they gathered feedback on comfort and design. This process allowed them to refine their product before launching it, resulting in a successful line that resonated with their target audience.

Case Study 2: A Tech Startup

A tech startup focused on developing a new wearable device. They used rapid prototyping to create multiple iterations of their product. Each version was tested by users, and feedback was incorporated into the next prototype. This iterative process not only improved the device's functionality but also helped the startup secure funding by demonstrating a clear understanding of user needs.

Implementing Rapid Prototyping in Your SME

If you're considering adopting rapid prototyping in your business, here are some steps to get started:

1. Define Your Goals

Before diving into prototyping, clearly outline what you want to achieve. Are you testing a new product idea, improving an existing one, or exploring new features? Having a clear goal will guide your prototyping efforts.

2. Choose the Right Tools

Select the appropriate tools and technologies for your prototyping needs. Depending on your product, you may use 3D printing, computer-aided design (CAD) software, or even simple materials like cardboard for low-fidelity prototypes.

3. Involve Stakeholders Early

Engage team members and potential users in the prototyping process. Their insights will be invaluable in refining your designs and ensuring that the final product meets market needs.

4. Test and Iterate

Once you have a prototype, conduct tests to gather feedback. Use this information to make necessary adjustments and create new iterations. This cycle of testing and refining is crucial for successful rapid prototyping.

5. Launch and Learn

After finalizing your prototype, move towards production. However, continue to gather feedback post-launch. This ongoing learning process will help you adapt and improve your products over time.

Challenges of Rapid Prototyping

While rapid prototyping offers numerous benefits, it is not without challenges. Here are some common obstacles SMEs may face:

Limited Resources

Many SMEs operate with tight budgets and limited staff. Rapid prototyping requires investment in tools and materials, which can be a barrier for some businesses. However, there are affordable options available, such as online 3D printing services.

Skill Gaps

Not all SMEs have the in-house expertise needed for effective prototyping. Training staff or hiring skilled professionals can be costly. Consider partnering with local universities or design firms to access expertise without a long-term commitment.

Balancing Speed and Quality

While speed is a key advantage of rapid prototyping, it is essential not to sacrifice quality. Ensure that your prototypes are functional and representative of the final product to gather meaningful feedback.

The Future of Rapid Prototyping for SMEs

As technology continues to evolve, the future of rapid prototyping looks promising for SMEs. Advancements in materials, software, and manufacturing techniques will make prototyping even more accessible and efficient. Here are a few trends to watch:

Increased Use of AI and Machine Learning

Artificial intelligence and machine learning can enhance the prototyping process by analyzing user data and predicting design outcomes. This technology will enable SMEs to create more user-centered products faster.

Sustainable Materials

With a growing emphasis on sustainability, the development of eco-friendly materials for prototyping is on the rise. SMEs can leverage these materials to create products that align with consumer values.

Collaborative Platforms

Online platforms that facilitate collaboration among designers, engineers, and users will become more prevalent. These tools will streamline the prototyping process and foster innovation.

Conclusion

Rapid prototyping is a game-changer for SMEs looking to innovate and stay competitive. By embracing this approach, businesses can accelerate their product development, reduce costs, and improve quality. As technology advances, the opportunities for rapid prototyping will only expand, making it an essential strategy for SMEs in the future.

To get started, define your goals, choose the right tools, and engage stakeholders early in the process. With the right approach, rapid prototyping can transform your business and lead to successful product launches. Embrace the future of innovation and make rapid prototyping a core part of your development strategy.

Comments