Reliable Small Batch Production in Digital Manufacturing

- I-Solids

- Dec 23, 2025

- 4 min read

In the rapidly evolving landscape of manufacturing, small batch production has emerged as a vital strategy for businesses seeking flexibility, quality, and efficiency. With the advent of digital manufacturing technologies, companies can now produce smaller quantities of goods without sacrificing quality or incurring excessive costs. This blog post explores the significance of reliable small batch production in digital manufacturing, highlighting its benefits, challenges, and practical applications.

Understanding Small Batch Production

Small batch production refers to the manufacturing of goods in limited quantities, typically ranging from a few units to several hundred. This approach contrasts with mass production, where large volumes of identical products are created. Small batch production is particularly advantageous for businesses that prioritize customization, rapid prototyping, and quick market entry.

Benefits of Small Batch Production

Customization and Flexibility

Small batch production allows manufacturers to tailor products to specific customer needs. This flexibility is crucial in industries where consumer preferences change rapidly, such as fashion and electronics.

Reduced Inventory Costs

By producing smaller quantities, businesses can minimize inventory holding costs. This approach reduces the risk of overproduction and waste, leading to a more sustainable manufacturing process.

Faster Time to Market

With digital manufacturing technologies, companies can quickly design, prototype, and produce small batches of products. This speed enables businesses to respond swiftly to market demands and trends.

Quality Control

Smaller production runs facilitate closer monitoring of quality. Manufacturers can identify and rectify defects more easily, ensuring that each product meets high standards.

Lower Capital Investment

Small batch production often requires less upfront investment compared to mass production. This accessibility allows startups and smaller companies to enter the market without significant financial risk.

The Role of Digital Manufacturing

Digital manufacturing encompasses a range of technologies, including 3D printing, computer-aided design (CAD), and advanced robotics. These technologies play a crucial role in enabling reliable small batch production.

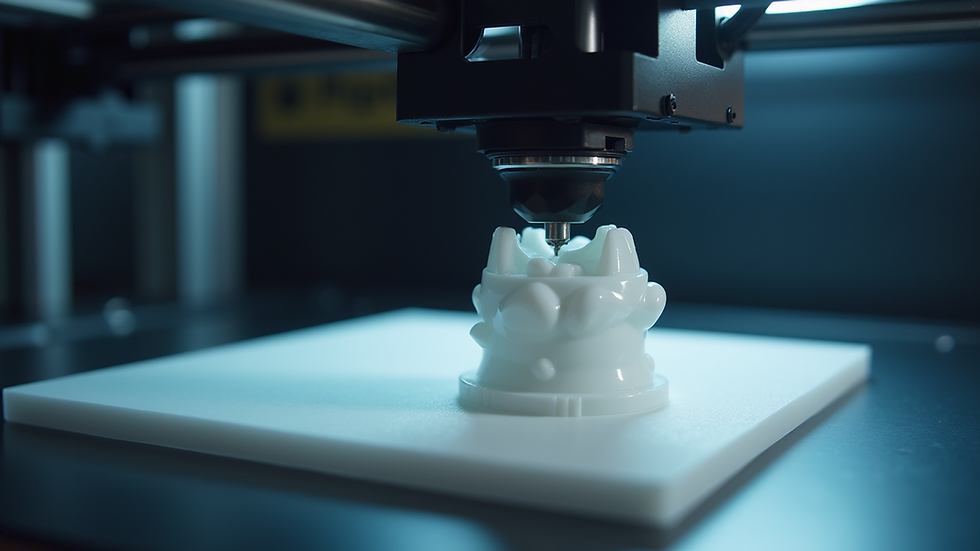

3D Printing

3D printing, or additive manufacturing, is a game-changer for small batch production. It allows for the creation of complex geometries and customized designs without the need for expensive molds or tooling. For example, a company producing bespoke medical devices can quickly iterate on designs and produce small quantities tailored to individual patients.

Computer-Aided Design (CAD)

CAD software streamlines the design process, enabling manufacturers to create detailed digital models of their products. This technology allows for rapid prototyping, where companies can test and refine their designs before moving to production. By integrating CAD with digital manufacturing, businesses can achieve a seamless workflow from concept to finished product.

Advanced Robotics

Robotic automation enhances efficiency in small batch production. Robots can perform repetitive tasks with precision, reducing the likelihood of human error. For instance, a small-scale electronics manufacturer can use robots to assemble components, ensuring consistent quality across each batch.

Challenges of Small Batch Production

While small batch production offers numerous advantages, it also presents challenges that manufacturers must navigate.

Higher Per-Unit Costs

Producing smaller quantities can lead to higher per-unit costs compared to mass production. This is due to the fixed costs associated with setup and production that are spread over fewer units. Manufacturers must find ways to optimize processes to mitigate these costs.

Limited Economies of Scale

Small batch production may limit the ability to achieve economies of scale. As production volumes increase, the cost per unit typically decreases. Manufacturers must balance the benefits of small batch production with the potential cost implications.

Supply Chain Complexity

Managing a supply chain for small batch production can be more complex than for mass production. Manufacturers need to ensure that materials and components are available in the right quantities and at the right time. This requires effective communication and coordination with suppliers.

Practical Applications of Small Batch Production

Small batch production is being successfully implemented across various industries. Here are some notable examples:

Fashion Industry

In the fashion industry, brands are increasingly adopting small batch production to create limited-edition collections. This approach not only caters to consumer demand for unique items but also reduces waste associated with unsold inventory. For instance, a sustainable fashion brand may produce a small run of garments using eco-friendly materials, appealing to environmentally conscious consumers.

Aerospace and Defense

The aerospace and defense sectors often require highly specialized components that may not be feasible to produce in large quantities. Small batch production allows manufacturers to create custom parts for aircraft and military equipment, ensuring compliance with stringent quality standards. Companies can leverage 3D printing to produce lightweight components that enhance performance and reduce costs.

Medical Devices

The medical device industry benefits significantly from small batch production. Custom prosthetics, implants, and surgical instruments can be produced to meet the specific needs of patients. Digital manufacturing technologies enable rapid prototyping and production, allowing healthcare providers to deliver personalized solutions efficiently.

Strategies for Successful Small Batch Production

To maximize the benefits of small batch production, manufacturers should consider the following strategies:

Invest in Technology

Investing in digital manufacturing technologies is essential for achieving reliable small batch production. Companies should explore options such as 3D printing, CAD software, and automation to enhance efficiency and quality.

Optimize Supply Chain Management

Effective supply chain management is crucial for small batch production. Manufacturers should establish strong relationships with suppliers and implement just-in-time inventory practices to ensure materials are available when needed.

Focus on Quality Assurance

Implementing robust quality assurance processes is vital for maintaining product standards. Manufacturers should conduct regular inspections and testing to identify and address any issues promptly.

Foster Collaboration

Collaboration between design, engineering, and production teams can streamline the small batch production process. Encouraging open communication and feedback can lead to continuous improvement and innovation.

Conclusion

Reliable small batch production in digital manufacturing offers businesses a pathway to flexibility, quality, and efficiency. By leveraging advanced technologies and adopting strategic practices, manufacturers can navigate the challenges associated with small batch production while reaping its numerous benefits. As the demand for customization and rapid market response continues to grow, small batch production will play an increasingly vital role in the future of manufacturing.

Embracing this approach not only positions companies for success but also fosters a more sustainable and responsive manufacturing ecosystem. Whether you are a startup or an established player, exploring small batch production could be the key to unlocking new opportunities in today's dynamic market.

Comments