Transforming Concepts into Precision Parts with i-SoLIDS

- I-Solids

- Dec 23, 2025

- 3 min read

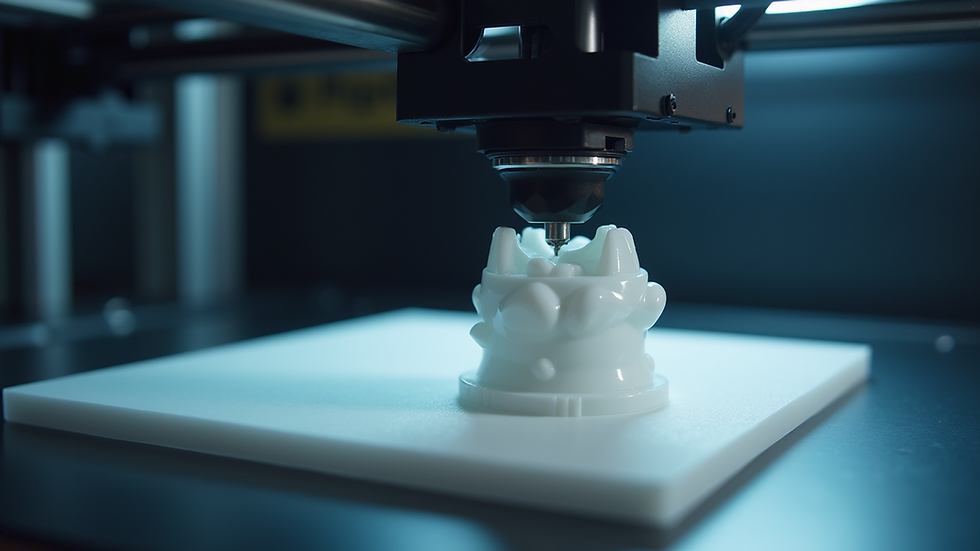

In today's fast-paced manufacturing landscape, the ability to transform ideas into tangible products is more critical than ever. Companies are constantly seeking ways to innovate and improve their processes. Enter i-SoLIDS, a powerful tool that bridges the gap between conceptual design and precision manufacturing. This blog post delves into how i-SoLIDS is revolutionizing the way we create parts, enhancing efficiency, accuracy, and overall productivity.

Understanding i-SoLIDS

i-SoLIDS is a sophisticated software solution designed for the manufacturing industry. It allows engineers and designers to create detailed 3D models and simulations of parts before they are produced. This capability is essential for several reasons:

Accuracy: By visualizing the part in a virtual environment, designers can identify potential issues early in the design process.

Efficiency: The software streamlines the workflow, reducing the time spent on revisions and modifications.

Cost-Effectiveness: Early detection of design flaws can save significant costs associated with material waste and production delays.

Key Features of i-SoLIDS

i-SoLIDS boasts several features that make it a standout choice for manufacturers:

3D Modeling: Create intricate designs with precision.

Simulation Tools: Test how parts will perform under various conditions.

Collaboration Capabilities: Share designs with team members for feedback and improvements.

Integration with Manufacturing Systems: Seamlessly connect with CNC machines and other manufacturing equipment.

The Importance of Precision in Manufacturing

Precision is paramount in manufacturing, especially in industries such as aerospace, automotive, and medical devices. A small error in design can lead to catastrophic failures, safety hazards, and significant financial losses. Here’s why precision matters:

Safety: In sectors like aerospace and healthcare, precision can be a matter of life and death.

Quality Control: High precision ensures that products meet stringent quality standards.

Customer Satisfaction: Delivering products that meet or exceed expectations fosters trust and loyalty.

Case Study: Aerospace Industry

Consider the aerospace industry, where i-SoLIDS has made a significant impact. A leading aerospace manufacturer utilized i-SoLIDS to design a new component for an aircraft engine. By using the software's simulation tools, the team identified a design flaw that could have led to engine failure. This early detection not only saved the company millions in potential recalls but also ensured the safety of countless passengers.

How i-SoLIDS Enhances the Design Process

The design process is often fraught with challenges, from initial concept to final production. i-SoLIDS addresses these challenges head-on:

Streamlined Workflow

With i-SoLIDS, the design process becomes more streamlined. Designers can quickly iterate on their ideas, making adjustments in real-time. This agility allows teams to respond to feedback and changes in project scope without significant delays.

Enhanced Collaboration

Collaboration is key in any design project. i-SoLIDS facilitates this by allowing multiple users to access and modify designs simultaneously. This feature ensures that everyone is on the same page, reducing the likelihood of miscommunication and errors.

Real-Time Feedback

One of the standout features of i-SoLIDS is its ability to provide real-time feedback on designs. As changes are made, the software analyzes the impact on the overall design, allowing teams to make informed decisions quickly.

The Future of Manufacturing with i-SoLIDS

As technology continues to evolve, so too does the manufacturing landscape. i-SoLIDS is at the forefront of this evolution, paving the way for smarter, more efficient manufacturing processes. Here are some trends to watch:

Increased Automation

The integration of i-SoLIDS with automated manufacturing systems is set to revolutionize production lines. By automating the transition from design to manufacturing, companies can reduce lead times and increase output.

Advanced Materials

As new materials are developed, i-SoLIDS will adapt to accommodate these innovations. This flexibility will enable manufacturers to explore new possibilities in product design and functionality.

Sustainability

Sustainability is becoming a critical focus for manufacturers. i-SoLIDS can help companies design products that use less material and energy, contributing to a more sustainable future.

Conclusion

The ability to transform concepts into precision parts is essential for success in today's manufacturing environment. i-SoLIDS stands out as a powerful tool that enhances accuracy, efficiency, and collaboration throughout the design process. By embracing this technology, manufacturers can not only improve their processes but also ensure the safety and satisfaction of their customers.

As we look to the future, the integration of i-SoLIDS with advanced manufacturing techniques will undoubtedly shape the industry. Companies that adopt this technology will be better positioned to innovate and thrive in an ever-changing landscape.

For those interested in exploring how i-SoLIDS can benefit their operations, consider reaching out to a representative for a demonstration or consultation. The future of precision manufacturing is here, and it starts with i-SoLIDS.

Comments